Buyers Today aren’t Shy About Paying More : Rajesh Sonkar

The incense industry has overcome the recession that COVID brought. With the rise in prices of raw materials, a rise in demand for high quality premium products is also being noticed. Rajesh Vishwanath Sonkar, head of S.L. Agarbatti in conversation with Sugandh India highlights how quality is trending now. The consumer is ready to pay the high price for premium and high quality products. Buyers today aren’t shy about paying more. Some even shelve 25,000₹ happily just for a single agarbatti stick! The challenge now is not the rise of raw material prices but the quality and attractive packaging. Companies are now purchasing raw materials at inflated prices and selling at lower margin but their sale volumes have increased. Before the price rise, a manufacturer used to do business of one lakh. Today it is five lakh. With the rise in prices and lower margins on one hand, the increase in sale volume on the other has surely balanced it out.

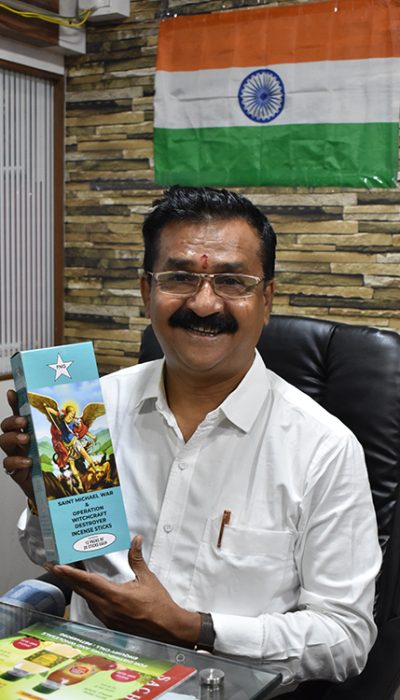

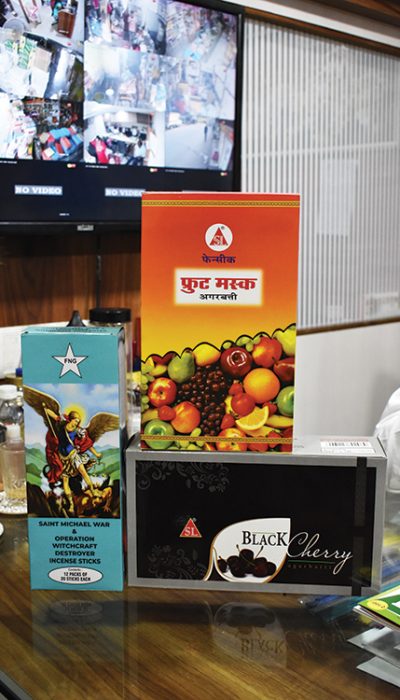

Rajesh Vishwanath Sonkar, Founder of S.L. Agarbatti Co. gave a brief insight about his company. He said “, I come from Amravati in Maharashtra. I was a sales guy. I started agarbatti business way back in 1998. Manufacturing came much later. It took me around two decades to reach here. My corporate office is in Mumbai and today, my business has a portfolio of over 450 incense products. Masala agarbatti, sold in premium and super-premium segments will cost you between 250₹ to 1200₹ and some to even 2500₹ a Kilo. For general retail our dhoop and agarbattis are priced at 15₹ and go upto 50₹.” Talking about his business he said “, Besides my home state, my company is selling in Assam and Odisha. Of late, we entered UP and we are getting good response.” Adding to it he said “, My company is strengthening logistics in other states as well. We’ve begun developing a strong supply chain.”

On asking about exports, Mr. Sonkar mentioned,” We export to African countries.” Elucidating about Africa he said “, Africans have a strong desire for fancy fragrances. Nonetheless, the demand for traditional perfumes for worshipping and religious occasions never dies. Here’s something you might like to know. In our country, people normally light two to five agarbattis for worshipping. In Africa, they light the whole bundle! Our exports are entirely different in terms of fragrances.”

Going back to the early days Rajesh said “, I had to work my way out to reach here. I started in Amravati (in Maharashtra). I made around ten kilos of raw agarbatti and sold them. That was the mid and late nineties. I supplied agarbattis on a motorcycle. I faced loss after loss. I lacked experience and tact. My first ten years were a big learning curve.” Talking about the growth seen in the industry he said “, This industry is growing rapidly. The future is bright. Dhoop and Agarbatti are not just for worshipping anymore. Lighting an agarbatti or a dhoop isn’t restricted to homes and places of worship. Moreover, the young generation has started buying incense products. Spas, meditation centres, clubs and hookah parlours are part of the customer base now. Agarbatti has evolved from a pooja product to a room freshener. Products are hitting the market as per the new trends.”

How to make a product successful? To this he said, “once you have created a quality product with an attractive packaging, it is now the distributor who will push the product in the market.” He added,” A company can make the best product but cannot sell it itself in the market. The selling part lies in the hands of the distributor and his network.”

Sugandh India wanted to know, how agarbatti companies are working on challenges. To this he replied “, With the increase in demand, more number of manufacturers are also rising. To tackle this we keep improving quality and produce new products.With giants like ITC already here, the word is out that Reliance is entering this market and so we have to keep updating our portfolio to stay in business.” Adding further, he continued “, There is no competition from local manufacturers. Their infrastructure is limited by; product availability, product quality and the number of customers. Regional brands might give some competition. Fly-by-night companies cannot survive for long. They are thrown out. Only established companies like ours are in a position to face losses and move business across states.”

Adding further he said “, Suppose a big manufacturer made 50 tons of agarbatti and for some reason, he could not sell. He’ll dump the stock and sell it in scrap to recover a part of the loss. This disturbs the market.

“How do you run your business outside Maharashtra with high logistic costs?” asked Sugandh India. To this, he replied “, I understand the traits of this market. I and my team fully understand that to remain visible in regions outside my home state, I have to make my products available over-the-counter: at any cost. Initially when the orders are low, the margins are low as well but as the quantity increases, we start getting profits too. So when we begin operating in a new region, we incur the obvious losses initially. The prices for the other states are kept to balance out losses and margins.

Adding more insight he said “,Dhoops sell less in maharashtra but heremore dhoop and agarbattis are sold than any other state. Bamboo shortage is not an issue. Maharashtra demands quality and attractive packaging. I can offload any quantity of incense goods outside my state. I know the quality we are delivering. Demand for agarbatti has increased manifolds here. Most sellable price-band is between 15₹ to 50₹.”

Clarifying the issue of shortage of bamboo, he adds,” there used to be shortage but no more, even Jigat is well available now.” Coming to the new trends, he said” Agarbattis made from cow dung is trending. Factories in Gujarat are coming up, especially for the manufacturing of such agarbattis. Cow dung powder is also being made available. As per the demand our company will begin operations shortly.” And regard the use of waste flowers, he added, “ the demand has increased but it cannot completely replace the existing process.”

Concluding the interview he informed, “ Womenfolk constitute 70% of the total workforce. Not only women are working in factories but are also part of our office staff; with not just production, they are successful in the Sales department as well.”