02 Sep Ocean’s Deep Printers, Leader in Agarbatti Packaging

–90 years legacy in Printing & Packaging: Shripal Patel

Ocean’s Deep Printers, is a renowned name in the field of packaging and printing with a legacy of 90 years. The company offers attractive and best in class packaging and printing solutions for the incense sticks and fabric industry across Gujarat and all over India The company, which started in 1932 as Honest Printery, is now known as Ocean’s Deep Printers.

Shripal Patel, Head of Ocean’s Deep Printers, shares with Sugandh India how in 1932 his grandfather started Honest Printery and later his father late Shri Ramesh Bhai Patel took over the business. As the family grew, he founded Ocean’s Deep Printers in 1995. Shripal ji told that his father used to make boxes for incense sticks earlier, but he picked a different segment under his firm Ocean’s Deep Printers and started the printing and packaging of Garment boxes. Today, Shripal ji’s sons, Vrund Patel and Shubh Patel have joined him as well.

While Vrund looks after the flexible pouch division, Shubh on the other hand is responsible for rigid box and canister round packaging. Shripal ji remembers how back then, garment companies of Gujarat would source the packaging boxes from Mumbai, but he started giving the same quality back at home and turned the tables.

Responding to a question, he said that Ocean’s Deep Printers is known for innovation in packaging. Due to the best in class quality that he provides, people from Mumbai purchase the boxes from us. Our garments business was going well, but after my father passed away in 1998, I took over the incense stick packaging division as well. Gradually the company started getting a lot of work in the agarbatti industry. Meanwhile, in the year 2014, the the garments industry hit a slow down as multi-national companies started entering Indian market. Eventually, our focus shifted mostly towards the incense stick industry. Today 70-80% of our clients are from incense stick industry.

Shripal ji said that we have made huge advancements by continuously adopting high-end technology in printing and packaging. Today we stand at a place where we can provide our clients with a finished product packaging sample within half an hour. From designing to printing all under one roof.

On a question regarding what machines he has, he told that we have Six Colour Heidelberg printing machine for UV and drip off printing, Israeli company machine called Scodix for digital foil, UV and emboss, digital cutter, digital printing machine. All the machines we have are best in class and as per international standards. In response to a question, he said that there is fierce competition in the market for packaging and there is always a demand for new type of designs. In the dhoop and incense sticks industry, there is a demand for technologically advanced and attractive boxes and zipper packaging.

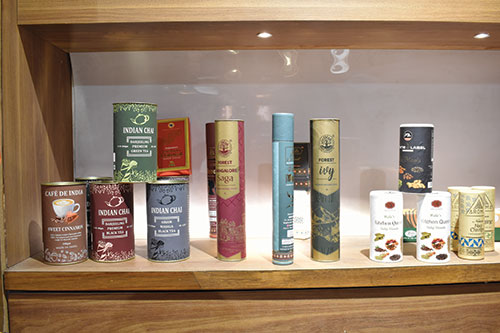

He told that be it the order of a single box or thousands of boxes, he gets it done. The difference is that the cost of making a box or packaging is high, the higher the quantity, the lower the cost. The new trend in packaging is that premium quality products are coming out every day and they cater to the demand and value of the brand. With his printing facility he is able to produce zipper pouches, rigid boxes and canister round. For a beautiful packaging and design, there is a team of more than 15 artists who are skilled enough create any kind of innovative designs in single day. Clients come in the morning get their design and printing done and leave by evening.

On the increase in the prices of raw materials, he said that the prices of paper, printing and raw materials have increased. Cost of everything has increased due to the increase in the prices of petrol and diesel. In such a situation, you have to work by reducing your margin. He creates different packaging and designs for each brand and its product. The customer first sees the packaging, gives his own design idea, or we show him a variety of designs. In this way, the printing and packaging are done as per the demand of the companies. In response to a question, he said that he has been rewarded by many states for best in class printing, packaging and design. He also makes boxes for Reliance Garment. Apart from this, they also provide printing and packaging solutions to Food, Pharma, Toy industry. Shripal ji said in response to a question that he also works for companies from USA.

There is definitely a problem with the quality and size of the paper. Responding to a question, he said that there is not much crisis in the agarbatti industry. Even during the Covid crisis, the industry did face much of a downfall. According to the needs of the industry, he also produces inexpensive printing and box materials for small-scale manufacturers and local producers. Even if there is an order or 1000 stickers, he gets the job done. That is, we provide printing solutions to even those that have lesser or cheaper requirement. We also guide manufacturers for what kind and which grade of packaging be it would be best for them and their budget , be it cheaper. In this way customers also feel that we are treating them with honesty.

No Comments