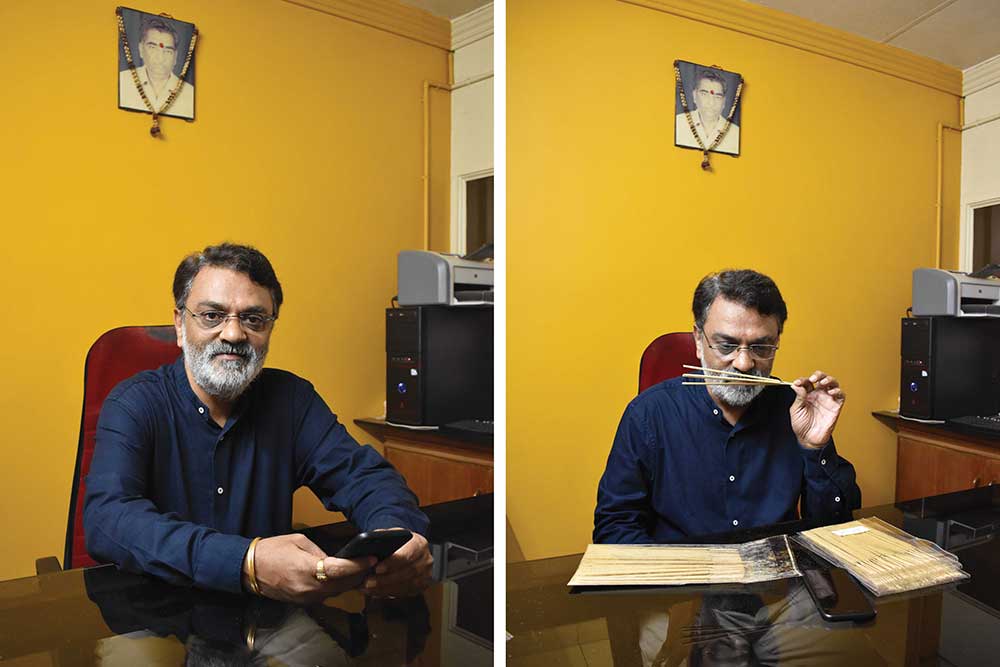

The connoisseur in masala agarbatti : – Chetan Ramani

Chetan Bhai Ramani is a Gujarat-based masala agarbatti manufacturer. He owns Ramani Cottage Industries in Ahmedabad. His main business is, supplying unbranded raw materials and masala agarbatti to branded agarbatti companies for the last 50 years.Chetan Bhai knows the art of masala making (mix) for agarbatti, dhoop and masala-batti. He learnt it from his father. Speaking to Sugandh India, he said “, The overall quality of an agarbatti depends on the quality of the raw materials. They have to be natural, genuine and of high grade.

” He said that they are making masala batti in-house and supplying it to branded companies. This they are doing for the last ten years. He said “, Everything is ours; be it raw materials, or perfume. The companies we supply to just do the packaging and sell in their name.”

The business was very good until China intercepted the domestic market. Manufacturers and suppliers had a hard time selling their own goods against Chinese rates. China and Vietnam were selling raw batti and killing the market. Buyers here didn’t actually know, what masala batti is and how it is made. All this is over now. There is a blanket ban on importing from these countries.

Talking about the art of making masala batti Chetan Bhai said “, gum, resin and frankincense (Loban) are mixed. The fragrance is not added afterwards. When it comes to making masala agarbatti, fragrance and essential oils are a part of the mix. In the case of raw agarbatti, perfume is mixed with DEP oil. The fragrance of masala batti is mild and lingers in the air for a longer period. Now since, the market recovered post-ban, the supply of raw materials and spices has improved.” Taking a cue on imports he said “, There was no need to import raw materials from these countries. We have enough of ours!”

He said that Ramani Cottage Industries produces in bulk and has its own distinct premium market. He said that not many people are aware of the difference between Masala Agarbatti and Raw Batti. Nowadays people start incense sticks business for 10-15 thousand rupees, but they are not able to give quality in their products at such a low cost and then they have to get out of the market. On the main challenge of the industry, he said that the price of raw materials has gone up. To deal with this, everyone has had to reduce their profits. Right now people are working on very low profits. At present, the market situation and raw material prices do not show any reduction or improvement. In such a situation, work is being done with less profit by producing more.

In response to a question, he said that the market of traditional fragrances like Gulab, Bela, Champa and Mogra is permanent. There was an era of fruity and other fragrances in between, but the old fragrances are making a comeback. Most of the supply of Masala Batti and Raw Materials is from traditional fragrances. Now the production of hand-made incense sticks has reduced. More work is being done on machines. In response to a question, he said that Gujarat has now become a hub of the incense and incense sticks industry. Around 1970 my father started the business of raw material of incense sticks.

He said that one thing that has always been is that the profit and price that the manufacturers of Bangalore enjoy, other state manufacturers don’t. Perhaps that is why Ahmedabad became the centre of cheap economy brand incense sticks. Both domestic consumption and exports increased here. At present, Ahmedabad has become a better market than Bangalore.

There is a new trend in the incense industry these days-the production of incense sticks using old flowers offered in temples, cow dung and other natural ingredients. Chetan Bhai responds to this saying that this will attract a select few consumers but cow dung and old flowers and other ingredients like these cannot meet the production demand of incense sticks on a large scale. Its market will always be limited.

On the latest trends happening in Masala Batti, he said that in Masala Batti, the use of wood powder is in trend now. The wood powder used to come from China earlier but now it is also available here. Wood powdered incense sticks just look good because of the different colours but there is no difference in quality. You can also make white stick from it. On the challenges faced by the industry, he said that now this trade has become completely localised. Competition has increased because of machines. Large-scale production is taking place at the local level, especially Raw Batti is being produced locally and its consumption is also mostly being done in Gujarat.